- English

- Françai

- Español

- Deutsch

- Română

- العربية

- 한국어

- 日本語

- Italiano

- Português

- Gaeilge

- Dansk

- Čeština

- Русский

- Afrikaans

- Euskara

- Català

- Esperanto

- हिन्दी

- Ελληνικά

- Bahasa Melayu

- Polski

- Српски

- Kiswahili

- ภาษาไทย

- Tiếng Việt

- Türkçe

- Svenska

- Cymraeg

- Slovenčina

- Latviešu

- Malti

- Magyar

- Galego

- ગુજરાતી

- Eesti Keel

- বাংলা

- Shqip

- беларуская мова

- Nederlands

- Tagalog

- ქართული

- Íslenska

- Kreyòl Ayisyen

- Lietuvių

- Norsk

- slovenščina

- தமிழ்

- Українська

- ײִדיש

- اردو

- తెలుగు

- فارسی

- македонски

- ಕನ್ನಡ

- Bahasa Indonesia

- עברית

- Suomi

- Hrvatski

- Български

- Azerbaijani

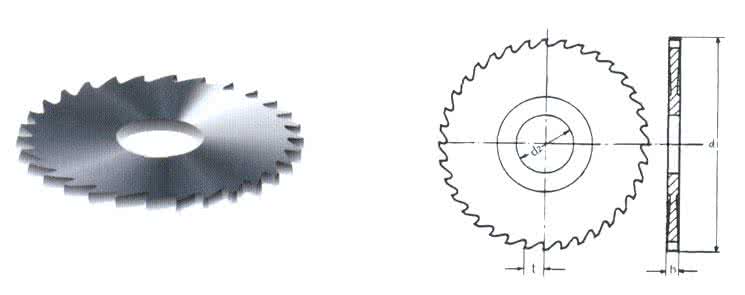

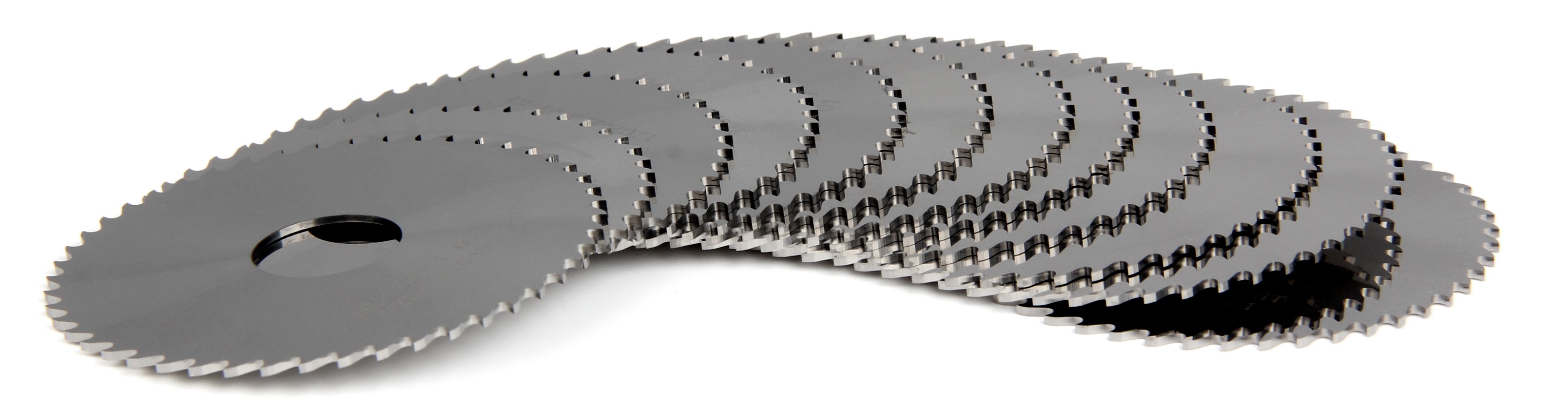

Tungsten carbide round cutting saw blades

Carbide saw blade cutter

Sizes : 75*25.4*T1.0-72T

Suitable for Metal and wood Machining

Hardness : 92.6 HRA

Teeth : 72T

Tungsten carbide round cutting saw blades

Most of the saw cutters are made of the same kind of high speed steel, carbide and other materials. Compared with high speed steel, the carbide has higher hardness, stronger cutting force, higher speed and feed rate, and higher productivity.

Widely used in: glasses, watches, machinery, electronics, motors and other industries

Advantages of Tungsten carbide round cutting saw blades, carbide saw cutters

1. With submicron grain size ,Good wear-resistent,long service life.

2. With strict tolerance extent control

3. Enjoy excellent wear resistance & high toughnes

4. A special Hot Isostatic Press (HIP) process provides quality improvement to the finished products to ensure meterial reliability

5. We carefully select the grade required for optimal cutting performance based on years of experience in the field

| External diameter(D) | Thickness(H) | Inner diameter(d) | Teet(T) |

| 25 | 0.2--5.0 | 6 8 10 | 10--58 |

| 30 | 0.2--5.0 | 6 8 10 | 10--60 |

| 32 | 0.2--6.0 | 6 8 10 12.7 | 10--60 |

| 35 | 0.2--6.0 | 8 10 12.7 | 10--60 |

| 40 | 0.2--6.0 | 8 10 12.7 | 10--80 |

| 45 | 0.2--8.0 | 10 12.7 16 | 10--80 |

| 50 | 0.2--8.0 | 10 12.7 16 | 10--100 |

| 55 | 0.2--8.0 | 12.7 16 | 24--120 |

| 60 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 63 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 70 | 0.3--8.0 | 16 22 25.4 | 28--120 |

| 75 | 0.5--8.0 | 16 22 25 4 | 30--120 |

| 80 | 0.5--8.0 | 22 25.4 | 30--128 |

| 85 | 0.5--8.0 | 22 25.4 | 30--128 |

| 90 | 0.5--8.0 | 22 25.4 | 30--160 |

| 100 | 0.5--8.0 | 22 25.4 27 | 30--160 |

| 110 | 0.8--8.0 | 22 25.4 27 32 | 30--180 |

| 120 | 1.0--10.0 | 22 25.4 27 32 | 30-240 |

| 125 | 1.0--10.0 | 22 25.4 27 | 30-240 |

| 150 | 1.0--10.0 | 22 25.4 27 32 | 40-240 |

Tool material composition:

C) TRS greater than or equal to 3800 N/mm²;

Iyo kambani ine yakazara blade yekugadzira michina yekugadzira michina mutsara kubva paupfu kugadzirwa kwezvinhu, kugadzira mold, kudzvanya, kudzvanya sinter, kugaya, kupeta uye kupeta mushure mekurapa. Inotarisa pakutsvagisa uye kuvandudzwa kwezvinhu zvepasi, groove chimiro, kunyatso kuumbwa uye kuvharika kwepamusoro kwecarbide NC inoisa, uye inogara ichivandudza machining kunyatsoita, hupenyu hwebasa uye zvimwe zvekucheka zvivakwa zvecarbide NC inoisa. Mushure memakore anopfuura gumi ekutsvagisa kwesainzi uye hunyanzvi, kambani yakabata akati wandei yakazvimirira tekinoroji, ine yakazvimiririra R&D uye dhizaini kugona, uye inogona kupa yakagadziridzwa kugadzirwa kune wega mutengi.